The data set out herein are not binding and can be changed at any time.

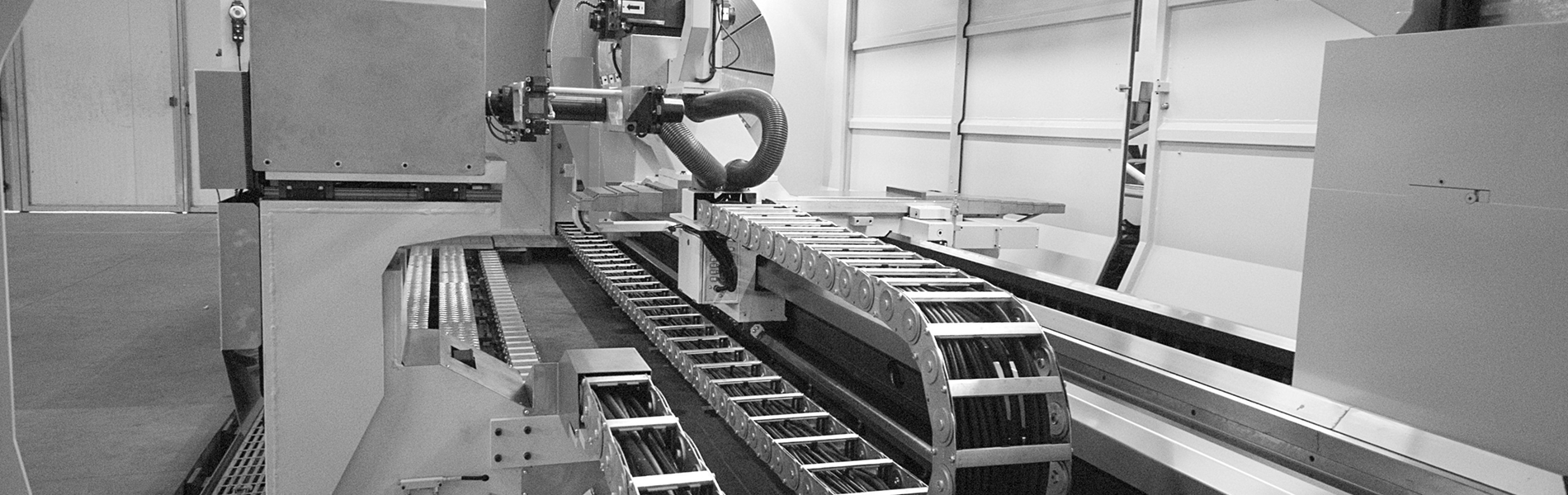

Titano evo

The characteristics

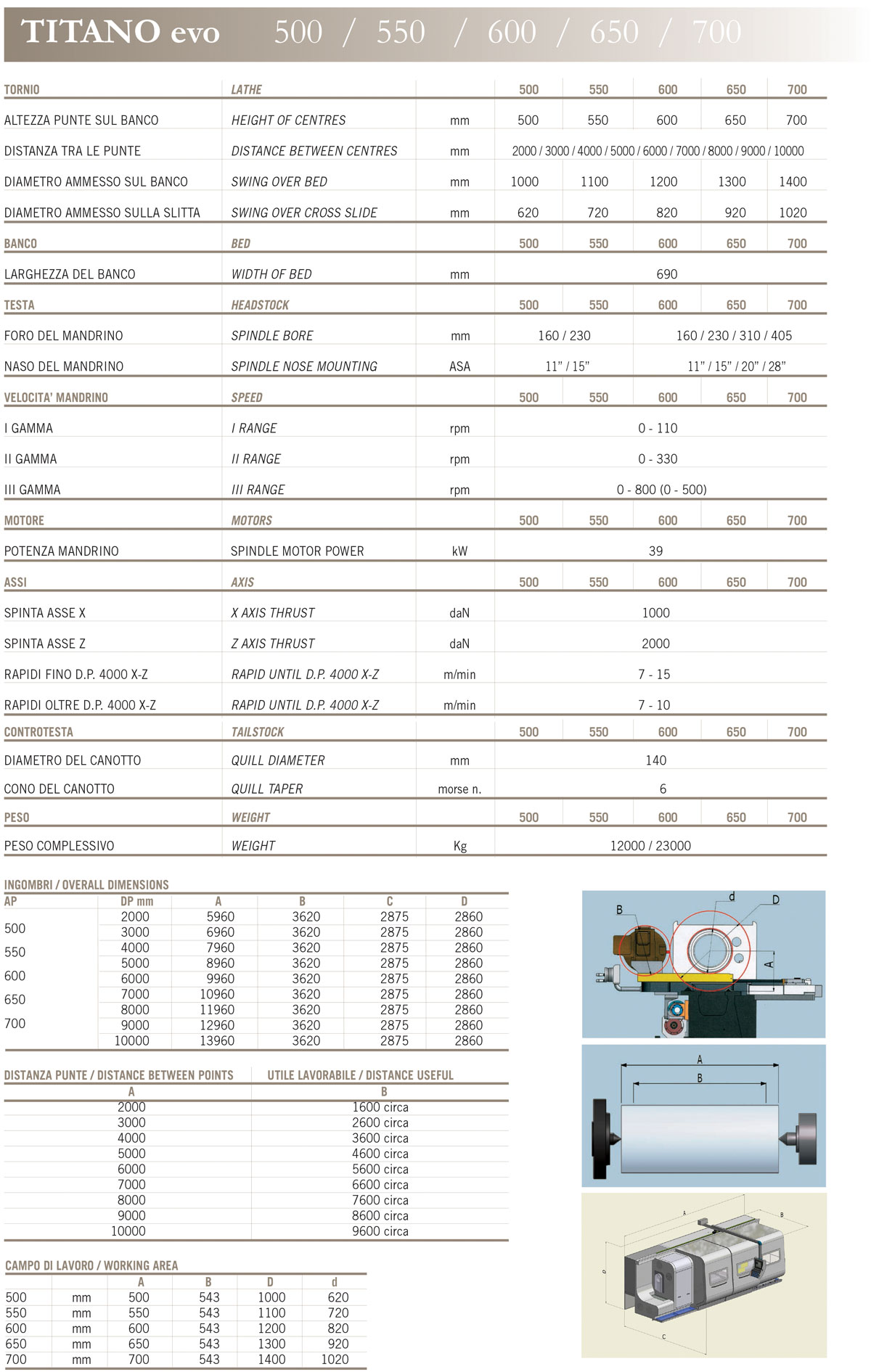

Conventional lathe with advanced conversational CNC, it stands out for its extremely simple programming, which is unique in the global market, with an exclusive control developed by Comev and Delectron for over 25 years. Fast, easy to use and reliable, powerful, perfect in production from the single piece to prototyping and in the small to medium series, built with care and top quality components. Already full of accessories, it is also suitable for advanced customisations to solve those particular problems where standard machines cannot be used.

Head

Extremely rigid monobloc casting, it houses the spindle assembled on high-precision bearings in order to obtain high-level gear precision and roughness. Casehardened and tempered spindle shaft, finely ground, oil lubricated with a special pump and flow sensor, housed in thermally stable casting, equipped with a hydraulically controlled 3-gear automatic gearbox.

Axes X and Z

Equipped with ISO 5 ground recirculating ball screws preloaded with 0 clearance and fitted on precision bearings, the relevant motors are aligned with said screws to ensure high dynamics and rigidity. The Titano series stands out for its acceleration, speed and power performance thanks to the special configuration of high torque motors.

Lubrication of the screws and guides is guaranteed by a high-pressure pump with multi-point distribution and dosing valves to ensure even distribution of the oil and low contamination of the coolant. All power supply cables of the various motors and devices are entirely protected by sheathing having IP 67 protection rating.

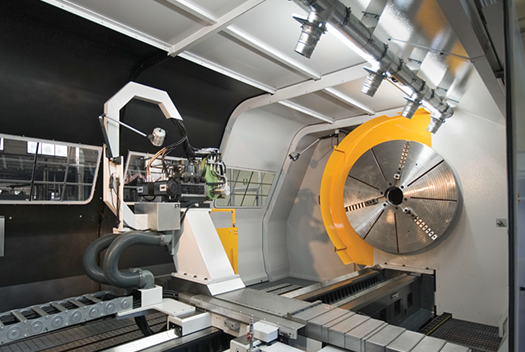

Carriage(s)

The well-sized carriage unit is rigid and stable in the various machining operations. The adequately sized X axis enables machining of the permitted diameter on the bench, even with horizontal axis disc turrets. The sliding guides that operate on the bench are equipped with glued and screwed, ground and scraped antifriction material. All carriages have tapered adjustment jibs. The continuous, high-resolution control handwheels inside the machine make operations easier, maintaining a conventional lathe approach.

Bench

It undergoes a natural ageing treatment before machining starts. Tempered on the top and bottom guides for long-term duration and ground in one single positioning on a modern CNC grinding machine. The monolithic casting with total ground support makes it extremely rigid, guaranteeing heavy machining with no vibrations. The special configuration of the 3 support guide makes it possible to have a wide operating range of the X axis while keeping it rigid and stable also at the maximum stroke, without undergoing any deformations.

Structural framework

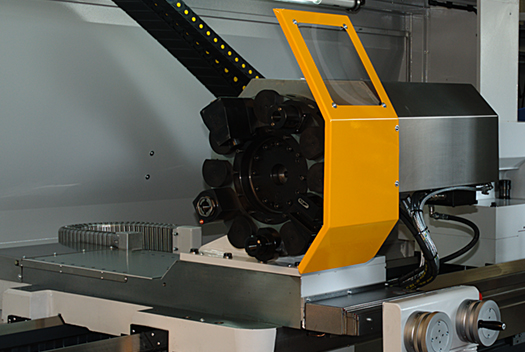

Completely enclosed to guarantee swarf and coolant containment, it has been designed to allow for easy piece unloading and loading and tooling, as well as guaranteeing operator safety.

Internally tempered and certified safety glass; they ensure perfect visibility of the work area.

Safety

Comev guarantees the highest standards of safety of its machines with the Dual Channel Safety System and Speed Manager integrated with safety PLC.

Tailstock

Sturdy monobloc casting with adjustable bed, finely scraped by hand for perfect coupling with the bench, equipped with hardened, tempered and ground sleeve with Vice taper housing and extraction slot. It can be conventionally or hydraulically controlled. Equipped with motorised transfer for easy positioning along the bench.

Numerical control

Exclusive Comev CNC, developed by capitalising on our experience but, above all, that of our partner customers who, in over 25 years, have contributed to creating unique operator-friendly software, which makes programming and use of the machine extremely simple, fast and safe. It enables machining with open doors in manual mode and closed doors in automatic mode. Equipped with diagnostics and remote assistance programs to minimise servicing and machine downtimes and to also support our customers in the programming stage, USB connection network card. It can be upgraded over time with new performance features that are developed and customised according to the specific needs of the customer.

Accessories supplied

Fixed points, spindle bore reduction taper, coolant tank complete with electric pump and wheels, centralised lubrication, steel spindle shield, carriage shield, complete structural framework, complete technical documentation, service keys.

Optional accessories

Fixed and mobile steady rests, 4 or 8-position electrical and mechanical turrets, motorised tools and C-axis, swarf remover, boring bar holder, hydraulic tailstock, hydraulic steady rests, bar-pusher, dedicated loading and unloading systems, measurement probes, tool presetting, mechanical, pneumatic, hydraulic spindle, independent 4-clamp platforms.