The data set out herein are not binding and can be changed at any time.

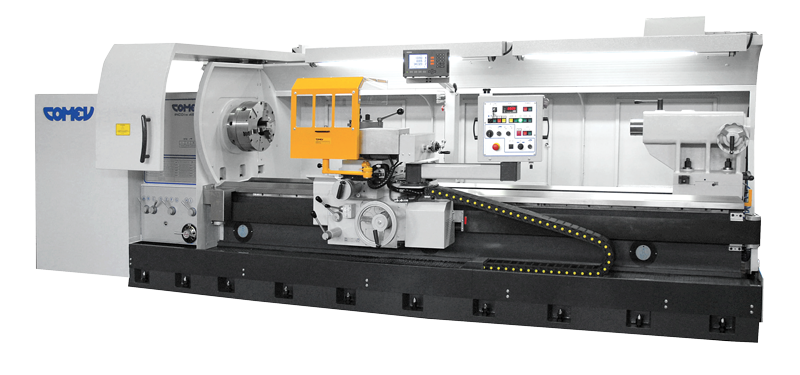

Traditional Picotre T

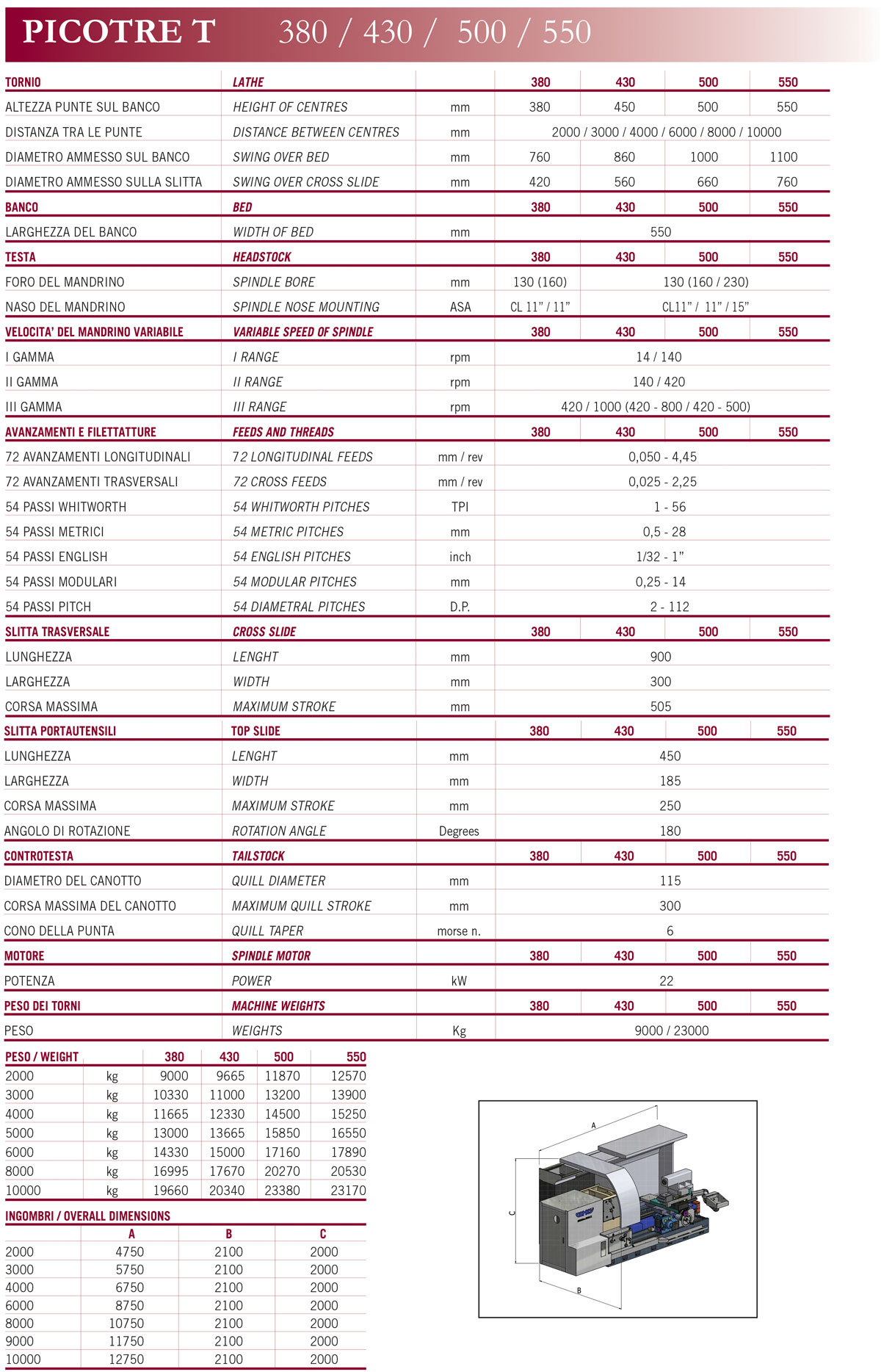

The characteristics

Heavy traditional parallel lathe with a considerably large monolithic base on the ground. Very powerful for processing medium-heavy and long workpieces.

Head

High-resistance cast iron structure with special ribbing to ensure rigidity, it contains a 3-speed automatic gearbox. The gears and shafts are made of special technically treated steel. The finely ground spindle shaft is supported by high-precision Timken or SKF bearings. The rotation speed within the selected gear can be changed by means of an inverter, which guarantees considerable power to cope with demanding machining operations.

Norton Box

The enclosed monobloc casting in an oil bath contains gears and shafts in C40, tempered, ground and mounted on bearings. It can obtain 72 feed rates and 52 threading pitches without external gear changes in the various Metric, Whithworth, Diametral Pitch, English systems.

Carriage(s)

The suitably sized carriage is rigid and stable in the various machining modes whilst still being agile and sensitive during operations with the mechanical handwheels. Finely machined lead screws in 38 NcD4 steel with high resistance bronze nuts. The main carriage, which is finely scraped by hand for perfect coupling with the bench, is equipped with adjustment jibs.

Tailstock

Monobloc casting with adjustable bed, finely scraped by hand for perfect coupling with the bench, equipped with casehardened, tempered and ground sleeve with Vice taper housing and extraction slot.

Accessories supplied

Cam Lock flange, fixed and mobile steady rests, fixed points, spindle bore reduction taper, coolant tank complete with electric pump and wheels, steel spindle shield, carriage shield, adequately thick rear sheet metal guard, complete technical documentation, service keys.